Electrolyte Aeration Systems

Improving productivity and quality of copper

By equipping electrowinning cells with the Ancor Tecmin’s aeration system, an improvement in productivity and quality of copper is achieved, which is confirmed by the users of this system.

Studies on copper electrowinning process worldwide have conclusively shown that gentle agitation of the electrolyte improves convection, increasing the stock and availability of copper next to the cathodes, thereby allowing to increase current density, improve quality of the deposit and increase the current efficiency of the process.

Ancor Tecmin, for almost a decade, has been experimenting with different devices for agitating electrolyte. The system with air micro-bubbles at low pressure was improved over the years and today there are over a thousand copper electrowinning cells operating with these systems in the world.

This system is being adapted to be able to be efficiently installed in the existing cells in electrowinning tank houses. For this purpose, the key is an autonomous system of support that is easily adapted to the peculiarities of each cell and allows for installation during stops for cell waste removal, without loss of production.

Benefits

Users of Ancor Tecmin’s systems of electrolyte agitation confirm that these increase the quality of copper and the economic profitability of the electrowinning tank houses, through:

- The possibility of increasing the current density in existing plants while maintaining or improving the quality of the copper deposit and improving current efficiency.

- The possibility of obtaining high quality cathodes from electrolytes of lower-grade copper, potentially reducing bottlenecks of the SX plants.

- Installation and commissioning of the system in existing cells with no lost production time, taking advantage of scheduled waste rock removals.

- Potential reduction of acid mist when, through the agitation air, fine aerosol formation in the “explosions” of the oxygen bubbles from the surface of agitated electrolyte is mitigated.

- Minimum consumption of low-pressure air and inexpensive diffusing hoses.

- Simple controls for easy adjustment of airflow and agitation level regarding electrolyte flow and other operating parameters of the plant.

Structure and Operation

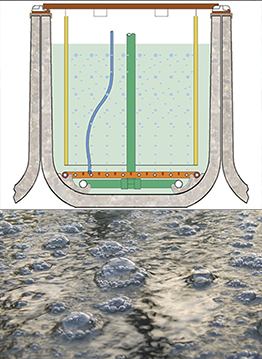

The heart of the system is a reticulated, self-supporting and one-piece structure molded into anticorrosive polymeric composite materials, which is accurately positioned in a horizontal plane under the electrodes, matching the cell plant. The perimeter of the structure encapsulates a tubular ring for isobaric distribution of external air for agitation at low pressure, which is connected to porous diffusing elements, passing longitudinally through the cell.

Predetermined low-pressure airflows emerge to the electrolyte in the plane of the structure under the electrodes through diffusers, forming micro-bubbles of controlled diameters in uniform and stable curtains or thermo-perforated hoses, forming random clouds of micro-bubbles of small diameters.

In turn, the power system of the cell is located below the micro-bubble generating system, and the electrolyte is discharged through pressurized jets directed to the inter electrode spaces from holes intentionally drilled to match the flows. The flow is designed ascending through the inter electrode spaces and in order to be fluidized by the air micro-bubbles, so that convection sweeps surfaces of the electrodes, reducing their external layers and thereby increasing the productivity of the electrodeposition.